Concrete is a marvel of construction. It builds our homes, bridges, and highways. But let’s face it—cracks and durability issues can ruin its reputation. What if I told you there’s a game-changer that makes concrete stronger, longer-lasting, and crack-resistant? Enter polypropylene fibers!

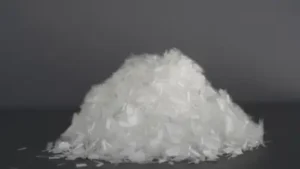

Polypropylene fibers are synthetic fibers that enhance concrete’s strength, durability, and resistance to cracks. By distributing stress and improving the matrix, these fibers revolutionize traditional concrete, turning it into a superhero material for modern construction.

Still intrigued? Let’s unravel the story of polypropylene fibers and how they’re transforming the concrete industry.

Why Use Polypropylene Fibers in Concrete?

1. What are polypropylene fibers made of?

Polypropylene fibers are crafted from thermoplastic polymers. These lightweight, high-strength fibers are designed to blend seamlessly into concrete, improving its structural integrity.

2. How do they prevent cracks?

They work by distributing stress evenly across the concrete matrix. This stops cracks from forming and spreading, especially during the critical drying phase.

3. Are polypropylene fibers eco-friendly?

Absolutely! They are recyclable and reduce the need for maintenance and repairs, minimizing the environmental footprint of concrete structures.

4. Where are these fibers most effective?

Polypropylene fibers shine in applications like flooring, pavements, precast elements, and lightweight structures. They’re versatile, making them a favorite across industries.

5. Are they expensive compared to traditional reinforcement?

While the initial cost might be slightly higher, the savings on maintenance and increased lifespan of structures make them a cost-effective choice.

How Do Polypropylene Fibers Enhance Concrete?

Shrinkage Crack Control

Concrete naturally shrinks as it dries, often leading to unsightly cracks. Polypropylene fibers act as tiny bridges within the matrix, preventing these cracks from forming.

Improved Durability

Adding fibers to concrete enhances its resistance to environmental stresses like freeze-thaw cycles, abrasion, and chemical exposure. This makes it ideal for industrial and outdoor applications.

Lightweight Yet Strong

Polypropylene fibers offer an incredible strength-to-weight ratio, allowing for lighter, more efficient designs without compromising performance.

What Are the Different Types of Polypropylene Fibers?

1. Monofilament Fibers

These are single-strand fibers that focus on controlling shrinkage cracks and enhancing durability. Ideal for general-purpose concrete.

2. Fibrillated Fibers

Fibrillated fibers are net-like structures that create a reinforcing web inside concrete, boosting its tensile strength.

3. Blended Fibers

A combination of monofilament and fibrillated fibers, these provide all-around benefits like improved impact resistance and better crack control.

Where Should You Use Polypropylene Fibers?

Industrial Floors

Factories, warehouses, and garages demand tough concrete. Polypropylene fibers make the material resistant to heavy loads and wear.

Pavements and Roads

Say goodbye to potholes and cracks! Fibers improve the longevity of roads and pavements, making them resilient to constant traffic and weathering.

Residential Construction

From driveways to patios, fibers ensure that your concrete surfaces remain flawless for years.

Debunking Myths About Polypropylene Fibers

1. “They weaken concrete.”

False. When mixed properly, these fibers strengthen concrete by increasing its tensile strength and crack resistance.

2. “Fibers make mixing complicated.”

Not at all! They integrate easily with standard mixing techniques, ensuring a uniform blend.

3. “Only large projects benefit from fibers.”

Wrong again. Fibers are equally effective in small-scale applications, making them a versatile choice for all builders.

Why Choose Fiberego?

We don’t just sell fibers; we provide solutions. At Fiberego, we design polypropylene fibers that suit your specific project needs. Whether you’re building a skyscraper or a simple walkway, we’ve got you covered. [Insert Placeholder Image]

Our fibers are:

- Durable

- Cost-effective

- Environmentally friendly

With a commitment to innovation and quality, we aim to be your trusted partner in creating stronger, more sustainable concrete structures.

Conclusion

Polypropylene fibers are redefining what concrete can do. By enhancing strength, reducing cracks, and boosting durability, they offer a modern solution for age-old challenges. Ready to take your concrete projects to the next level? Let’s build a stronger future together with Fiberego.