Concrete is one of the most important building materials in the world. It is strong, affordable, and suitable for all types of structures—from residential buildings to large infrastructure projects. However, concrete is not perfect. Because it is brittle, it can crack easily, especially when exposed to shrinking, temperature changes, or external pressure.

To solve this problem, reinforcing materials such as fibers are used in concrete mixtures. One of the most widely used reinforcing materials is cellulose fiber. It is natural, safe, and improves many physical properties of construction materials. In recent years, cellulose fiber has gradually become a popular additive in construction and industrial materials.

What Is Cellulose Fiber?

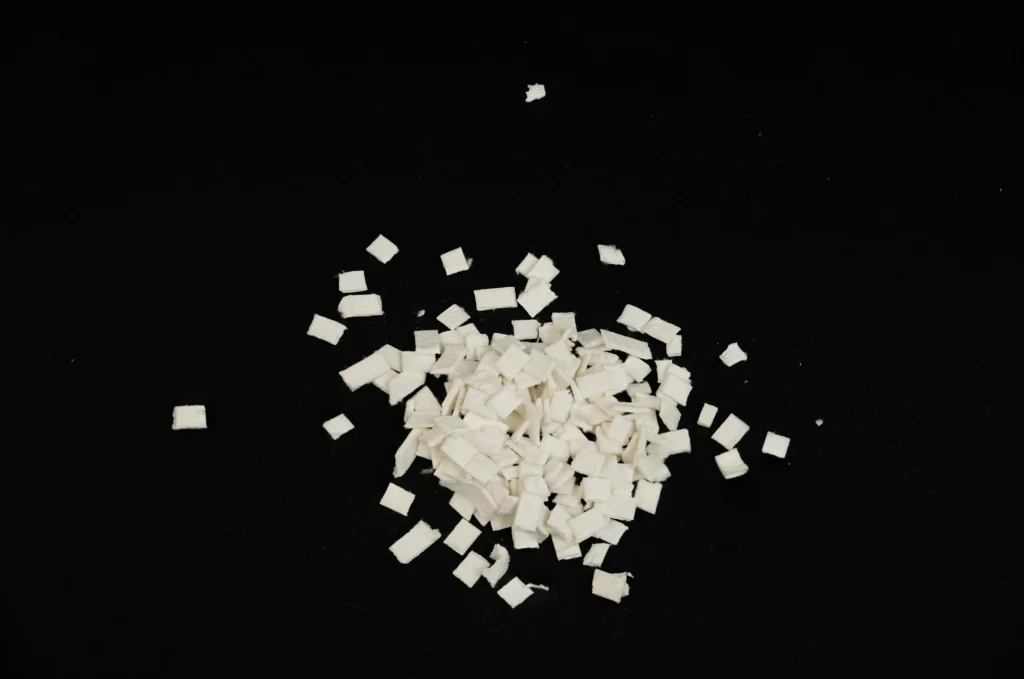

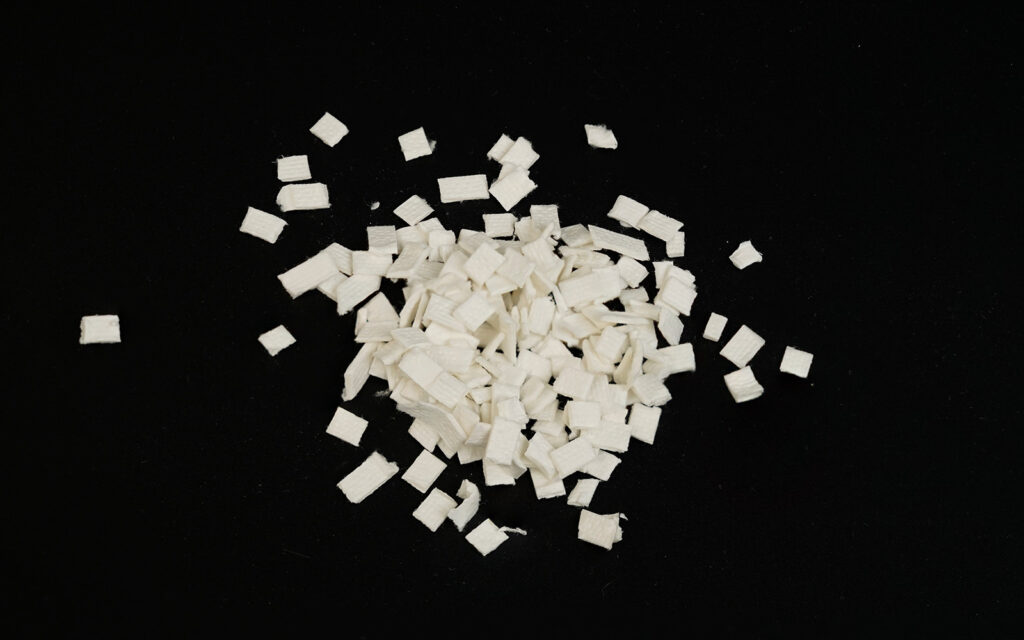

Cellulose fiber is a fiber material made from natural plant sources, mainly wood pulp, bamboo, cotton, and recycled paper. Cellulose itself is a natural polymer and is the primary structural component of plants. When processed into fine fibers, it forms cellulose fiber.

In simple words:

Cellulose fiber is a natural fiber extracted from plants and used to improve the performance of building materials like concrete, plaster, cement boards, and asphalt.

It has fine texture, great water absorption ability, excellent dispersibility, and high structural stability.

How Is Cellulose Fiber Produced?

The basic production process includes:

- Selecting plant raw material (wood pulp or recycled fiber)

- Purifying and separating cellulose components

- Processing them into micron-level fibers

- Grinding and drying

- Surface treatment to improve compatibility

After processing, cellulose fibers become stable and uniform in size, making them suitable for industrial mixing.

Types of Cellulose Fibers

Cellulose fibers can be classified according to their origin and structure. Here are the most common types used in construction materials:

1. Natural Plant-Based Cellulose Fiber

This type comes from:

- Pine wood

- Eucalyptus

- Bamboo

- Cotton fiber

- Sugarcane fiber

Processing removes impurities like lignin and hemicellulose, leaving pure cellulose fiber.

Characteristics:

- Biodegradable

- Good bonding with cement and gypsum

- High uniformity

- Lower manufacturing cost

This is the most commonly used cellulose fiber in construction products.

2. Regenerated Cellulose Fiber

This fiber does not come directly from plants but is regenerated through chemical processing.

Examples include:

- Rayon fiber

- Viscose fiber

- Lyocell fiber

These fibers are often smoother and stronger.

Characteristics:

- Very high purity

- Stable performance

- Uniform dimensions

Regenerated cellulose is often used where better performance control is required.

3. Microcrystalline Cellulose Fiber

This fiber is refined at micro-level sizes, usually less than 100 microns.

It is used in:

- High-precision building materials

- Dry-mixed mortar

- Cementitious coatings

- Chemical fillers

Microcellulose improves both flexibility and structural strength.

4. Recycled Cellulose Fiber

Often made from recycled paper or industrial waste.

While cheaper, performance varies depending on processing quality. It is widely used in cost-sensitive applications, especially in insulation and filling materials.

Benefits of Using Cellulose Fiber in Concrete

Why do more manufacturers and engineers use cellulose fiber in construction materials?

Here are the most important advantages:

1. Reduced Cracking and Shrinkage

Concrete naturally shrinks when it dries.

Shrinkage → tiny cracks

Tiny cracks → large cracks

Large cracks → structural weakness

Cellulose fiber limits this process in two ways:

- Improves internal bonding

- Distributes internal stress more evenly

When shrinkage happens, fibers work like reinforcement threads, preventing cracks from expanding.

2. Better Water Retention

In many dry-mix materials—such as mortar and gypsum products—water evaporates too fast.

Cellulose fibers absorb water and release it gradually, resulting in:

- Better hydration of cement

- Higher final strength

- Improved surface finish

This is especially useful when working under hot weather.

3. Increased Flexibility and Impact Strength

Concrete alone is rigid and brittle.

But with cellulose fiber:

- It becomes more flexible

- It tolerates deformation better

- It resists sudden external impact

This improves durability in floors, pavements, repair mortars, and decorative coatings.

4. Anti-Sagging and Thickening Effect

In tile adhesives, putty powder, wall plaster, and skim coats:

Materials may sag or slip during application.

Cellulose fiber creates a supporting network inside the mixture and:

- Prevents sliding

- Allows thicker coating layers

- Improves overall consistency

This makes construction easier, smoother, and more efficient.

5. Enhanced Bond Strength

Cellulose fiber improves adhesion between cement mortar and surfaces such as:

- Brick walls

- Concrete slab

- Ceramic tile

- Insulation boards

This helps prevent falling, peeling, or cracking over time.

6. Eco-Friendly and Renewable

Cellulose fiber:

- Comes from natural plants

- Produces low pollution

- Is biodegradable

- Does not release harmful chemicals

As sustainable construction trends rise, cellulose fiber becomes an ideal replacement for synthetic additives.

Applications of Cellulose Fiber in Construction

Cellulose fiber is widely used in building materials. Below are the most common usage fields.

1. Ready-Mixed and Dry-Mixed Mortar

In mortar products, cellulose fiber provides:

- Long open time

- Good workability

- High binding force

Typical construction types include:

- Tile adhesive

- Masonry mortar

- Repair mortar

- Grouting materials

2. Cement-Based Putty Powder and Wall Coatings

For wall finishing, cellulose fiber helps:

- Improve smoothness

- Reduce cracking

- Enhance water retention

- Improve attachment to substrate

Ideal for indoor and outdoor applications.

3. Fiber-Reinforced Concrete

Small percentages of cellulose fiber significantly improve toughness.

It is commonly used in:

- Sidewalk slabs

- Driveway repair

- Industrial flooring

- Decorative concrete

When combined with polymer additives, performance improves even more.

4. Gypsum-Based Construction Products

Gypsum materials dry fast. That can lead to cracking if water evaporates too quickly.

Cellulose fiber solves this problem by:

- Improving elasticity

- Delaying moisture loss

- Enhancing surface strength

Mainly used in:

- Plaster gypsum

- Gypsum wall panels

- Flexible gypsum putty

5. Cement Fiber Boards and Calcium Silicate Boards

Boards need reinforcement to maintain structural integrity.

Cellulose fiber strengthens the board internally, improving:

- Stability during curing

- Bending resistance

- Impact resistance

This increases service life and final strength.

Conclusion: Why Use Cellulose Fiber?

Cellulose fiber is a natural, stable, and cost-effective reinforcement material for modern construction. It improves the performance of concrete and mortar in many ways, including:

- Reducing cracking

- Improving flexibility

- Retaining water

- Enhancing adhesion

- Increasing impact resistance

It is safe, sustainable, and compatible with most cementitious systems.

With modern construction focusing on long-term durability, lower maintenance, and environmentally friendly materials, cellulose fiber is becoming more widely adopted by manufacturers, builders, and construction engineers.

If you want to improve the performance of cement-based materials, cellulose fiber is a smart and economical addition.