Twisted Bundle PP Fiber 50MM (TBPM B-50)

Twisted Bundle Polypropylene Fiber 50MM (TBPM B-50)?

What Is Twisted Bundle PP Fiber 50MM (TBPM B-50)?

Twisted Bundle PP Fiber (TBPM B-50) is an advanced synthetic macrofiber specifically engineered to reinforce concrete. By providing three-dimensional reinforcement, it enhances concrete’s structural integrity, reduces cracking, and ensures higher long-term durability in both static and dynamic conditions.

Unlike conventional reinforcement methods, TBPM B-50 offers optimal dispersion thanks to its twisted structure, ensuring uniform mixing within concrete. This makes it easier to apply while delivering consistent performance, reducing the need for steel reinforcement and cutting overall project costs.

Technical Specifications of Twisted Bundle PP Fiber 50MM (TBPM B-50)

| Item | Parameters |

| Composition | 100% virgin polypropylene |

| Diameter | 1.2mm |

| Length | 38-60mm(Customized) |

| Alkali&Acid Resistance | High |

| Tensile Strength | ≥400MPa |

| Elastic Modulus | ≥3.5GPa |

| Elongation | 20 – 25% |

| Melting Point | 160-170°c |

Fiberego - Advanced Fiber for Sustainable Concrete Construction

Key Benefits of Twisted Bundle PP Fiber 50MM (TBPM B-50)

- Enhanced Crack Resistance: The unique fiber design reduces both shrinkage and temperature-induced cracks, maintaining concrete stability and extending the service life of structures.

- Increased Load Capacity: Provides higher load-bearing strength, making concrete more resilient under heavy traffic, machinery, or structural stress in critical infrastructure.

- Superior Durability: Improves resistance against environmental factors such as freeze-thaw cycles, abrasion, and mechanical wear, ensuring long-lasting performance.

- Optimal Dispersion: Its twisted bundle form ensures even distribution in the mix, eliminating fiber clumping and providing uniform reinforcement throughout the concrete.

- Reduced Construction Costs: By minimizing or replacing traditional steel reinforcement, TBPM B-50 reduces material and labor expenses while maintaining performance.

- Excellent Environmental Resistance: Resistant to moisture, alkalis, and chemical degradation, the fiber preserves concrete’s integrity in harsh conditions.

Request a Free Sample

Experience the performance of Fiberego’s TBPM B-50 firsthand. Contact us today to request your free sample and technical datasheet, and see how our fibers can improve your next project.

Top 4 Applications of Twisted Bundle PP Fiber (TBPM B-50)

Industrial Flooring

Bridge Construction

Road Pavements

Airport Runways

Why Choose Fiberego as Your Twisted Bundle PP Fiber Supplier?

Certified Quality

All products meet international standards for strength, safety, and performance.

Customizable Fiber Solutions

We provide tailored fiber lengths, packaging, and specifications.

Expert Support

Our technical team guides you from product selection to application.

Global Reach

Reliable supply and service across multiple regions.

Innovation-Driven

Continuous R&D ensures high-performance and future-ready solutions.

Best Sellers

Twisted Bundle PP Fiber TBPM B-40

Reinforce concrete with Fiberego’s Polypropylene Twisted Fiber 40mm. Enhance crack resistance, tensile strength, and durability for industrial, transportation, and precast applications.

Twisted Bundle PP Fiber TBPM G-40

Enhance concrete durability with Fiberego’s Twisted Bundle PP Fiber 40mm. Improve crack resistance, strength, and flexibility for industrial, transportation, and precast applications.

Twisted Bundle PP Fiber TBPM B-54

Fiberego’s Twist-Bundle PP Fiber 54mm enhances concrete durability and crack resistance. Perfect for industrial, transportation, and precast applications.

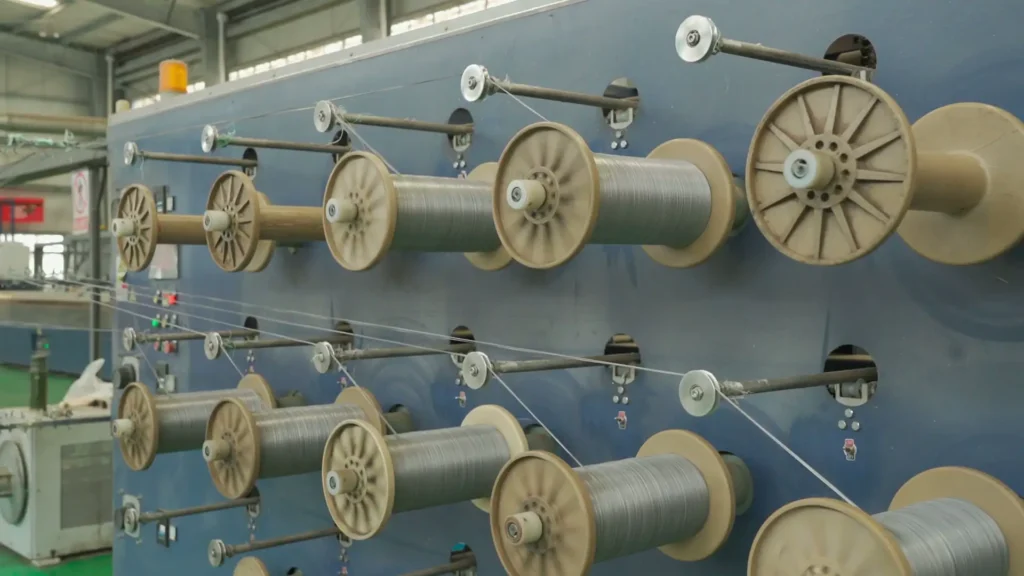

Fiberego Factory – State-Of-The-Art Production Facilities

Advanced Production Lines

We operate automated production facilities with strict quality control, ensuring every batch of fibers maintains uniform strength, flexibility, and durability.

Large-Scale Capacity

Our factory is designed to handle bulk orders efficiently, providing stable supply for large construction projects while maintaining competitive lead times.

Innovation & R&D Focus

Fiberego’s dedicated research team continuously develops new fiber solutions, helping clients achieve better reinforcement, cost savings, and sustainable construction practices.