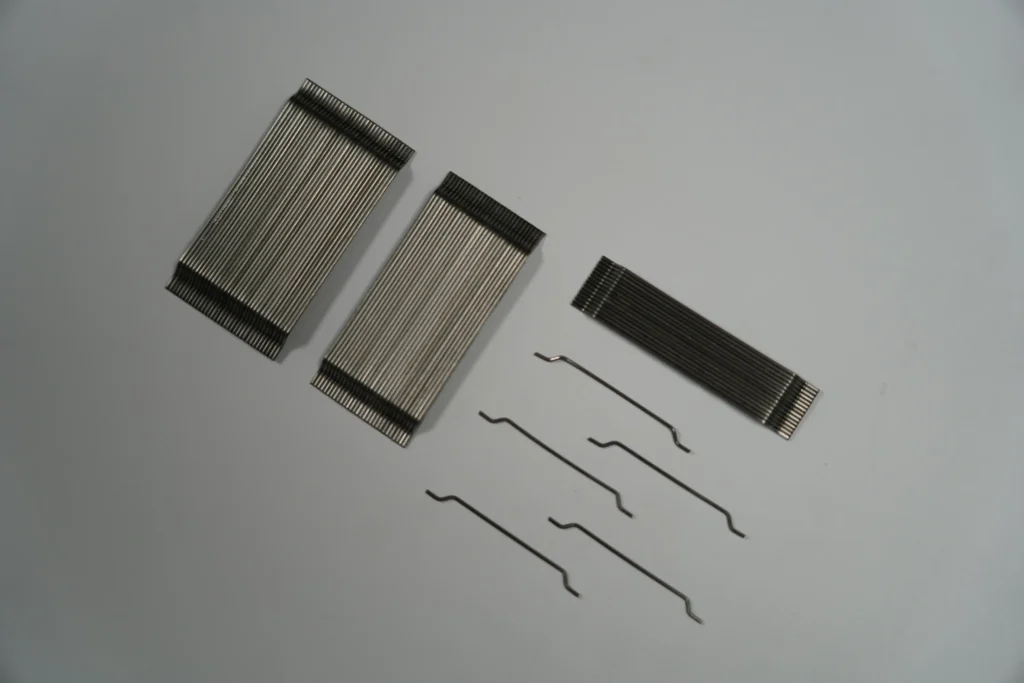

Glued Hooked End Steel Fiber 35mm

Fiberego - A leading steel fiber manufacturer in China

What Is Glued Hooked End Steel Fiber 35mm?

At Fiberego, we specialize in developing high-performance steel fibers for concrete reinforcement, and our Glued Hooked End Steel Fiber 35mm stands out as a reliable choice for projects that demand both strength and efficiency.

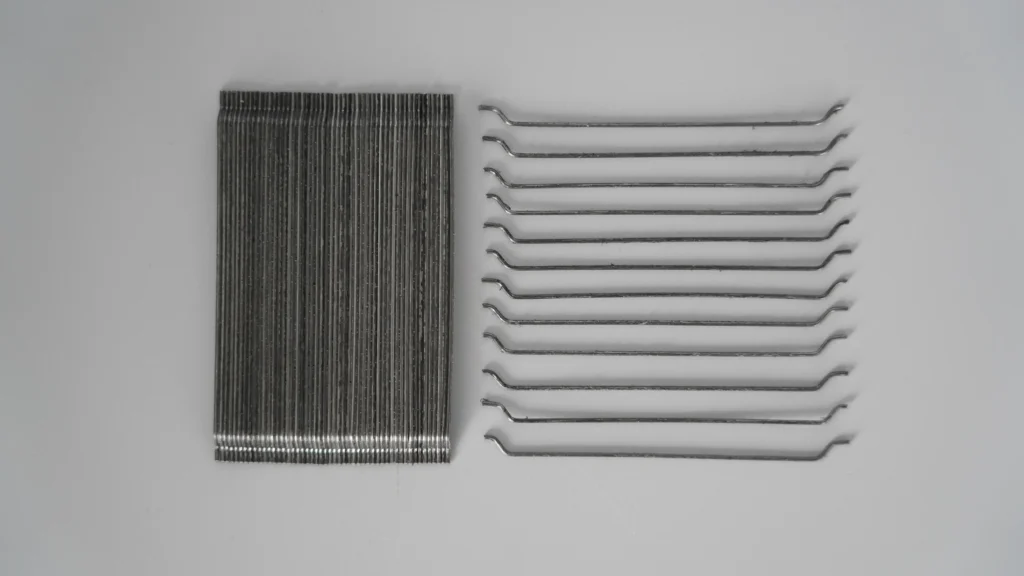

Each fiber is manufactured from high-tensile cold-drawn steel wire with precisely formed hooked ends, creating robust anchorage within the concrete matrix. The glued bundle formation simplifies storage, transport, and dosing while ensuring quick and even dispersion during mixing—eliminating clumping and saving time on-site.

Technical Specifications of Glued Hooked End Steel Fiber 35mm

Choosing the right steel fiber for your concrete project starts with reliable technical information. Fiberego provides precise product specifications to ensure our Glued Hooked End Steel Fiber 35mm meets your structural and performance requirements.

| Item | Parameters |

| Length | 35mm |

| Diameter | 0.5-1mm |

| Melting Point | 1495℃ |

| Tensile Strength | 1100-1850MPa |

| L/D Ratio | 60-80 |

Fiberego - Advanced Reinforcement for Durable Concrete Solutions

Key Benefits of Glued Hooked End Steel Fiber 35mm in Concrete Reinforcement

Fiberego’s Glued Hooked End Steel Fiber 35mm delivers multiple performance advantages that improve the quality, lifespan, and cost-effectiveness of reinforced concrete.

Superior Crack Resistance and Shrinkage Control

-

Minimizes plastic shrinkage and drying shrinkage cracks, a common issue in early-age concrete.

-

Reduces long-term cracking caused by temperature changes, heavy loads, or structural movement.

Enhanced Mechanical Strength and Load-Bearing Capacity

-

Increases tensile, flexural, and impact strength, making concrete more resistant to both static and dynamic loads.

-

Enhances fatigue resistance for heavily used structures such as industrial floors, runways, and bridge decks.

-

Improves ductility and post-crack load-bearing performance, reducing the risk of sudden failure.

Efficient and Uniform Dispersion During Mixing

-

Glued bundles break apart smoothly in mixers, ensuring even fiber distribution without fiber balling.

-

Simplifies dosing and handling, reducing labor costs and speeding up the construction process.

High Chemical and Corrosion Resistance

-

Provides resistance to alkalis, acids, and chlorides, making it ideal for marine, tunnel, and industrial environments.

-

Ensures long-lasting performance in aggressive chemical conditions.

Request a Free Sample

-

Request a Free Sample: Evaluate our fiber’s mixing performance, dispersion, and reinforcement effect in your own concrete trials before full-scale application.

-

Get the Technical Datasheet: Access detailed specifications, recommended dosages, and application guidelines to ensure optimal results.

Top 6 Applications of Glued Hooked End Steel Fiber 35mm in Construction

Industrial and Warehouse Flooring

-

Provides exceptional load-bearing capacity for high-traffic and heavy machinery areas.

-

Reduces the need for joints, leading to less maintenance and fewer repairs over time.

Tunnel Linings and Shotcrete

-

Improves adhesion and resistance to ground movement in underground tunnels.

-

Ensures reliable reinforcement in sprayed concrete applications for faster construction.

Airport Runways and Pavements

-

Withstands high wheel loads from aircraft and vehicles.

-

Enhances fatigue resistance under continuous thermal expansion and contraction.

Bridges and Road Construction

-

Increases structural toughness for high-load, high-traffic areas.

-

Minimizes cracking caused by vibration and dynamic stress.

Precast Concrete Elements

-

Ensures consistent strength and crack control in precast tunnel segments, pipes, slabs, and panels.

-

Reduces the need for additional steel reinforcement during manufacturing.

Marine and Coastal Structures

-

Resists chloride-induced corrosion in ports, harbors, and seawalls.

-

Maintains long-term structural performance in harsh marine conditions.

Why Choose Fiberego as Your Glued Hooked End Steel Fiber Supplier?

Certified Quality

Produced under strict quality control standards (ASTM, EN, ISO) to ensure consistency and reliability.

Customizable Options

Available in various lengths, diameters, and aspect ratios to meet your project needs.

Expert Support

Our team provides professional guidance on dosage, mixing, and design optimization.

Global Logistics

We ensure timely delivery for both small-scale and large-scale infrastructure projects.

Sustainable Solutions

Our fibers reduce material waste and contribute to long-lasting, low-maintenance structures.

Best Sellers

Hooked End Steel Fiber HE SF-35

Fiberego’s Hooked End Steel Fiber 35mm enhances concrete strength, crack resistance, and durability. Ideal for industrial floors, bridges, tunnels, and precast applications.

GLUED HOOKED END STEEL FIBER GHE SF-45

Fiberego’s Glued Steel Fiber 45mm enhances concrete strength, crack resistance, and durability. Ideal for industrial flooring, transportation, and precast applications.

GLUED HOOKED END STEEL FIBER GHE SF-60

Fiberego’s Glued Steel Fibre 60mm improves concrete strength, crack resistance, and durability. Ideal for industrial floors, highways, and precast infrastructure projects.

State-of-the-Art Facility and Streamlined Supply Chain

Inside Fiberego: Advanced Factory, Production Line, and Warehouse Facilities

Modern Manufacturing Plant

Our factory is designed for high-output production with fully automated lines for cold-drawing, cutting, hooking, and gluing steel fibers. This technology ensures consistent dimensions, precise tensile strength, and stable product performance for every order.

High-Capacity Production Line

Fiberego’s production lines operate with large-scale manufacturing capability, enabling us to handle both standard and custom orders without delays. Whether your project requires tens of tons or continuous bulk supply, we provide dependable delivery schedules.

Strategic Warehousing & Global Logistics

Contact Fiberego – Speak with Our Sales & Technical Experts

How We Support You

-

Professional Sales Team: Quick response, clear communication, and tailored quotations to match your project requirements.

-

Experienced Technical Team: Guidance on dosage, mixing techniques, and application recommendations to ensure optimal performance.

-

Global Assistance: Whether your project is local or international, our team offers flexible solutions and fast delivery arrangements.