Concrete is the backbone of modern construction. From high-rise buildings to pavements, it’s one of the most widely used building materials in the world thanks to its strength, versatility, and affordability. However, plain concrete has one major drawback—it’s brittle and prone to cracking under stress. To address this, steel reinforcement (or rebar) is commonly embedded in concrete to improve its tensile strength.

But as construction methods evolve, so do the ways we improve concrete performance. One of the most significant advancements is fiber-reinforced concrete, a material designed to enhance durability, reduce cracking, and improve overall performance.

What is Fiber-Reinforced Concrete?

Fiber-reinforced concrete (FRC) is essentially concrete mixed with discrete fibers that act as secondary reinforcement. These fibers are uniformly distributed throughout the mix to improve the material’s toughness and crack resistance.

The main purpose of adding fibers isn’t to replace steel rebar for structural reinforcement. Instead, it’s to control shrinkage cracks, increase impact resistance, and extend the life of the concrete. By dispersing fibers throughout the mix, stress points become more evenly distributed, which significantly reduces the likelihood of cracking.

Think of it as adding tiny reinforcements at every point of the concrete mass rather than just at specific locations like rebar. This makes FRC especially valuable in applications where durability, abrasion resistance, or improved surface quality is a priority.

Types and Uses of Fiber-Reinforced Concrete

Not all fibers are created equal. Different fiber types offer distinct benefits, making fiber-reinforced concrete a versatile material for a wide range of applications. Here’s a closer look at the most common types:

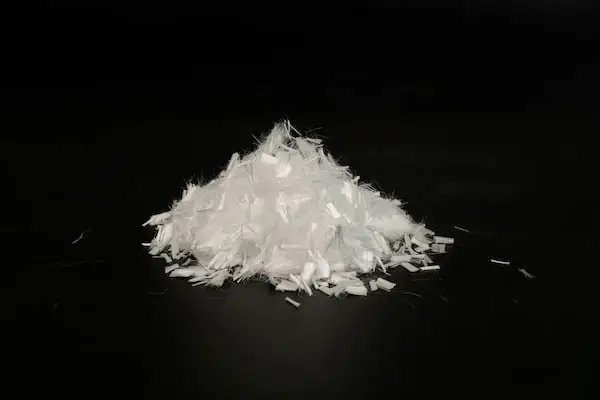

Polypropylene (PP) Fibre-Reinforced Concrete

Polypropylene (PP) fibers are synthetic fibers widely used to improve concrete’s abrasion resistance and ductility. These lightweight, non-corrosive fibers help control plastic shrinkage and drying shrinkage cracks, making them ideal for overlays, pavements, and industrial floors.

Another key advantage of PP fibers is their low thermal conductivity, which gives the concrete a degree of heat insulation—particularly useful in fire-prone environments or structures exposed to high temperatures.

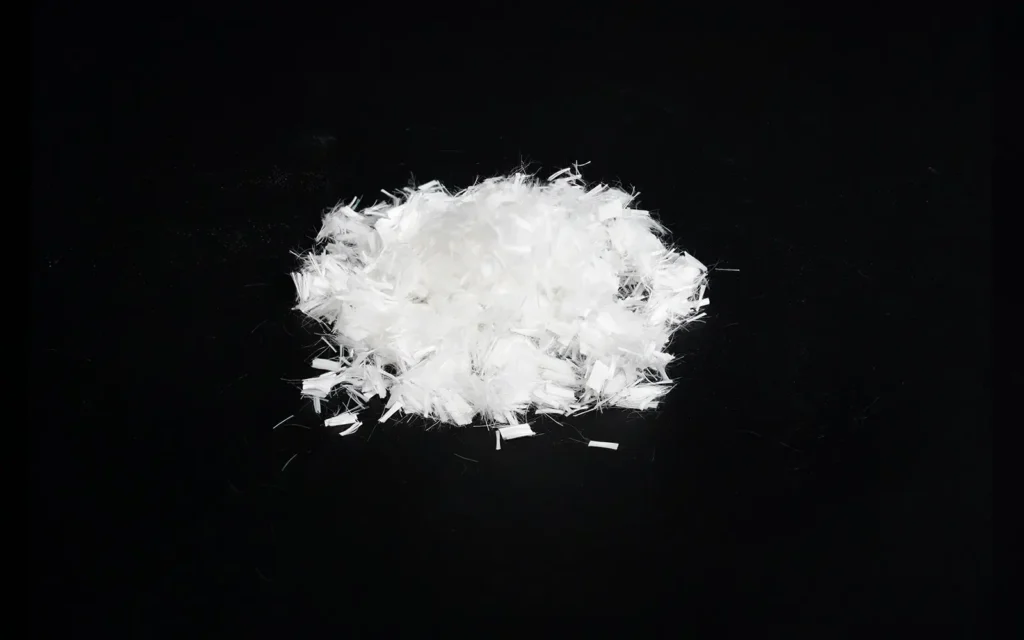

Polyester Fibre-Reinforced Concrete

Polyester fibers are valued for their durability and light weight. Unlike steel, polyester fibers do not rust, which means they’re ideal for structures exposed to moisture or corrosive environments.

They also improve compressive, flexural, and tensile strength, making the concrete more resilient under heavy loads. Because of their versatility, polyester fibers are frequently used in precast concrete products, thin wall panels, and repair mortars.

Steel Fibre-Reinforced Concrete (SFRC)

Steel fibers are the heavyweights of fiber reinforcement. They’re commonly used in industrial floors, pavements, airport runways, tunnels, and bridges. By distributing steel fibers throughout the concrete, you can reduce the need for traditional rebar in certain applications, control crack widths, and significantly increase impact and fatigue resistance.

Steel fiber-reinforced concrete is particularly suited for heavy-duty structures where performance and longevity are critical.

Polyvinyl Alcohol (PVA) Fibre-Reinforced Concrete

PVA fibers are known for their high tensile strength and ability to promote ductility in concrete. When micro-cracks form, these fibers bridge them and prevent further propagation, which improves the structural integrity of the material.

They’re often used for “hidden” applications where aesthetics matter—such as architectural panels or interior precast products—because they minimize visible cracking and improve the finish quality of the concrete surface.

Glass Fibre-Reinforced Concrete (GFRC)

Glass fibers are a cost-effective option with excellent alkali resistance. They’re lightweight, non-corrosive, and can serve both structural and decorative purposes.

GFRC is commonly used in architectural cladding panels, precast decorative elements, and thin, lightweight structures where traditional reinforcement isn’t feasible. This type of fiber-reinforced concrete allows architects and designers to experiment with textures and forms without compromising durability.

How is Fiber-Reinforced Concrete Made?

Making fiber-reinforced concrete involves more than just tossing fibers into a standard concrete mix. Proper proportioning and mixing are crucial to ensure the fibers are evenly dispersed and don’t clump together.

Key considerations include:

- Water-to-Cement Ratio: Maintaining the correct ratio is critical to achieve the desired workability and strength. Too much water can lead to weak concrete, while too little can make mixing difficult.

- Aspect Ratio of Fibers: The length-to-diameter ratio of fibers affects how well they bond with the concrete matrix. Higher aspect ratios typically improve crack control but may require more careful mixing.

- Uniform Dispersion: To maximize the benefits of fibers, they must be uniformly distributed throughout the mix. Specialized mixing techniques or fiber feeders are often used to achieve this.

Once mixed, fiber-reinforced concrete is placed and finished similarly to traditional concrete, although contractors may need to adjust techniques slightly to account for the fibers.

Advantages and Disadvantages of Fiber-Reinforced Concrete

Like any material, fiber-reinforced concrete has both advantages and drawbacks. Understanding these can help builders and engineers decide whether it’s the right choice for their projects.

What Are The Advantages of Fiber-Reinforced Concrete?

- Crack Control: Fibers help prevent both plastic shrinkage cracks and long-term drying shrinkage cracks.

- Improved Durability: The material stands up better to impact, abrasion, and fatigue, extending the life of structures.

- Enhanced Ductility: Fibers improve the post-crack behavior of concrete, making it tougher and less brittle.

- Reduced Maintenance Costs: With fewer cracks and better wear resistance, fiber-reinforced concrete often requires less maintenance over time.

- Supplement to Rebar: In some cases, fibers can reduce the amount of traditional reinforcement needed, offering potential cost savings.

What Are The Disadvantages of Fiber-Reinforced Concrete?

- Mixing Challenges: Improper mixing can lead to fiber balling or uneven dispersion, reducing the effectiveness of the reinforcement.

- Higher Initial Cost: Fiber-reinforced concrete generally costs more than plain concrete due to the added materials.

- Increased Weight: Depending on the type and quantity of fibers, the concrete can be heavier, which may affect handling and transportation.

Despite these drawbacks, many contractors find that the long-term benefits—reduced maintenance, improved performance, and enhanced durability—often outweigh the higher upfront costs.

Final Words

Fiber-reinforced concrete represents a major step forward in the evolution of construction materials. By combining the proven strength of concrete with the added benefits of fibers, builders can create structures that last longer, perform better, and resist cracking more effectively.

Whether you’re looking to improve industrial floors, precast elements, pavements, or architectural finishes, fiber-reinforced concrete offers a versatile solution to meet modern construction demands.

If you’re considering fiber-reinforced concrete for your next project, partnering with an experienced fiber manufacturer—like Fiberego—ensures you get high-quality fibers tailored to your application, along with expert guidance to maximize performance.