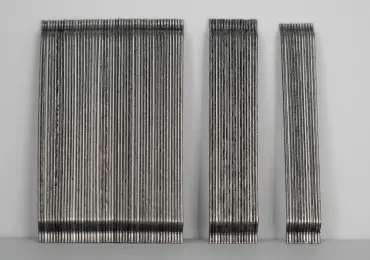

スチールファイバー

スチールファイバーコンクリート用途の優れた補強材

スチールファイバーGHE SF-35

フィベレゴの スチールファイバー 35mm コンクリートの強度、ひび割れ抵抗性、耐久性を高めます。工業用床材、インフラ、プレキャストプロジェクトに最適。

スチールファイバーGHE SF-60

フィベレゴの スチールファイバー接着 60mm コンクリートの強度、ひび割れ抵抗性、耐久性を向上させる。工業用フロア、高速道路、プレキャストインフラプロジェクトに最適。

ブラスコーティング・マイクロスチールファイバー BCM SF-06

フィベレゴの ブラス・コーティング・マイクロ・スチール・ファイバー 6mm コンクリートの強度、ひび割れ抵抗性、耐久性を高める。工業床、橋梁、プレキャスト用途に最適。

ブラスコーティング・マイクロスチールファイバー BCM SF-12

フィベレゴの 銅被覆スチール・ファイバー 12mm コンクリートの強度、ひび割れ抵抗性、耐久性を高めます。工業用床材、インフラ、プレキャスト部材に最適。

接着フック付エンド真鍮コーティング鋼繊維 GHEB SF-12

フィベレゴの ブラス・コーティング・フックド・エンド・スチールファイバー 12mm コンクリートの強度、ひび割れ抵抗性、耐久性を高めます。工業用床材、インフラ、プレキャスト部材に最適。

フック・エンド・スチール・ファイバーHE SF-35

フィベレゴの フック・エンド・スチール・ファイバー 35mm コンクリートの強度、ひび割れ抵抗性、耐久性を高める。工業床、橋梁、トンネル、プレキャスト用途に最適。

フック・エンド・スチール・ファイバーHE SF-45

フィベレゴの ルース・フック・エンド・スチール・ファイバー 45mm コンクリートの強度、ひび割れ抵抗性、耐久性を向上させる。工業床、橋梁、トンネル、プレキャスト用途に最適。

フック・エンド・スチール・ファイバーHE SF-60

フィベレゴの フック・エンド・スチール・ファイバー 60mm コンクリートの強度、ひび割れ抵抗性、耐久性を向上させる。工業用床材、橋梁、トンネル、プレキャスト用途に最適。

よくある質問

スチールファイバー は、コンクリートの機械的特性を向上させるために建設現場で広く使用されている補強材である。構造強度を向上させ、ひび割れ幅を縮小し、衝撃や摩耗に対する耐性を高める。

スチールファイバー 接着フックエンド・ファイバー、銅被覆マイクロ・スチール・ファイバー、真鍮被覆フックエンド・ファイバーなど、さまざまなタイプがあります。各タイプは、コンクリート・マトリックス内でユニークな接着特性と機械的固定を提供します。

スチールファイバー は通常、乾燥したコンクリートミックスに直接加えられる。最適な性能を得るために重要な均一な繊維分布を達成するために、十分な混合を行う。

最適な注入量は、プロジェクトの要件によって異なります。構造エンジニアに相談するか、メーカーのガイドラインを参照することで、特定の用途に適した量を決定することができます。

特定の状況において スチールファイバー は、鉄筋コンクリートの従来の鉄筋(「鉄筋」)を完全に置き換えることができる。これは、工業用床材で最も一般的ですが、その他のプレキャスト用途でもあります。一般的には、性能要件が満たされていることを確認するため、実験室試験で裏付けを取る。コンクリート内に鉄筋の最低量を課す場合もあるため、地域の設計基準要件が満たされていることを確認するよう注意する必要がある。