Structural Engineering

The Role of Fibers in Structural Engineering

Introdução

Structural engineering is at the heart of modern construction, ensuring buildings and infrastructure can withstand dynamic and static loads. Fibers—such as polypropylene, polyester, steel, and cellulose—are vital materials that enhance the strength, durability, and resilience of structures. Fiberego leads the industry in providing high-performance fibers tailored for structural engineering applications.

Types of Fibers in Structural Engineering

Polypropylene Fibers

Polypropylene fibers are lightweight yet robust, offering superior crack resistance and tensile strength. Their applications include:

- Foundations: Minimizing settlement cracks and improving load distribution.

- Load-Bearing Walls: Enhancing flexural strength and reducing shrinkage cracks.

- Industrial Floors: Providing resistance to abrasion and chemical damage.

Polyester Fibers

Polyester fibers are valued for their flexibility, UV resistance, and durability under varying environmental conditions. Key uses are:

- Concrete Pillars: Reinforcing vertical loads while resisting cracking under dynamic stresses.

- Parking Structures: Ensuring durability against vehicular impact and chemical exposure.

- Concrete Decks: Supporting lightweight, durable designs for large spans.

Steel Fibers

Steel fibers deliver unparalleled toughness and load-bearing capacity, making them ideal for:

- Reinforced Foundations: Enhancing strength in deep pile caps and mat foundations.

- Industrial Floors: Supporting heavy machinery and resisting impact loads.

- Pillars: Adding compressive strength and crack control in critical structural elements.

Cellulose Fibers

Cellulose fibers, derived from natural sources, are eco-friendly reinforcements that improve workability and water retention. Applications include:

- Load-Bearing Walls: Enhancing mortar adhesion and crack resistance.

- Concrete Decks: Improving surface finish and moisture retention for uniform curing.

- Sustainable Structures: Offering biodegradable options for environmentally conscious projects.

Fiber Applications in Structural Engineering

Foundations

Fibers enhance the stability and durability of foundations, ensuring they can support immense loads over time. Polypropylene fibers prevent shrinkage cracks, while steel fibers bolster compressive strength in high-stress zones.

Load-Bearing Walls

Load-bearing walls fortified with fibers exhibit improved tensile strength and reduced susceptibility to cracks caused by thermal or seismic movements. Polyester and cellulose fibers are particularly effective in achieving these outcomes.

Concrete Decks

Concrete decks often require lightweight but durable materials. Polyester fibers provide flexibility, while steel fibers ensure resistance to heavy loads and dynamic stresses. These combinations make them ideal for bridges and elevated platforms.

Industrial Floors

Fibers enhance the toughness and impact resistance of industrial floors, making them suitable for environments with heavy machinery and frequent traffic. Steel fibers excel in high-impact areas, while polypropylene fibers resist chemical erosion.

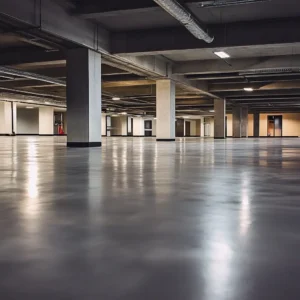

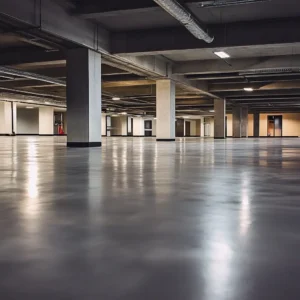

Parking Structures

Parking structures face constant wear and tear from vehicle loads, temperature changes, and chemical exposure. Polyester fibers offer excellent durability and flexibility, ensuring long-lasting performance.

Benefits of Fibers in Structural Engineering

Enhanced Strength and Durability

Fibers improve tensile and compressive strength, ensuring structures can endure both static and dynamic loads.

Crack Resistance

Fibers reduce shrinkage and thermal cracking in concrete, extending the service life of structures.

Cost Efficiency

Reinforced fibers reduce the need for extensive repairs, lowering maintenance costs over time.

Environmental Sustainability

Fibers like cellulose offer a biodegradable option, while synthetic fibers contribute to efficient material use and reduced waste.

Why Choose Fiberego for Fiber Solutions?

Fiberego is a trusted partner in structural engineering, providing advanced fiber solutions tailored to project-specific needs.

- Innovative Products: Fiberego offers a comprehensive range of fibers designed for diverse structural applications.

- Technical Expertise: Fiberego’s team ensures optimal fiber integration in construction projects.

- Sustainability Focus: Commitment to eco-friendly practices and materials for greener construction.

Future Innovations in Fiber-Reinforced Structures

Smart Fiber Technology

Embedding sensors within fibers to monitor structural health in real-time.

Hybrid Composites

Combining fiber types for enhanced performance in extreme conditions.

Biodegradable Fibers

Development of fully biodegradable fibers for eco-conscious structural projects.

Conclusão

Fibers are indispensable in modern structural engineering, providing solutions for foundational stability, crack resistance, and environmental sustainability. Fiberego’s expertise in polypropylene, polyester, steel, and cellulose fibers ensures that your projects are built to last, supporting strength, durability, and innovation in construction.

Trust Fiberego to reinforce your structures with cutting-edge fiber solutions for a sustainable future.