Elementos prefabricados de hormigón

Revolutionizing Precast Concrete with Fiberego Fibers

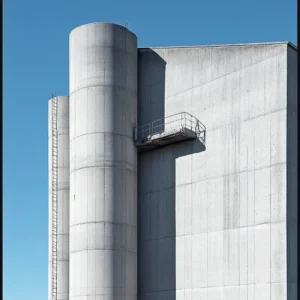

Introducción In the diverse and demanding sectors of construction and infrastructure, precast concrete elements stand out for their efficiency, durability, and versatility. Fiberego, leveraging its expertise in fiber technology, enhances these elements with a variety of fibers, including polypropylene, polyester, steel, and cellulose, to meet the rigorous demands of modern construction.

The Role of Fibers in Precast Concrete

- Polypropylene and Polyester Fibers These synthetic fibers provide crucial benefits to precast concrete by improving its impact resistance and durability. Used in everything from building construction to bridge girders, these fibers reduce the occurrence of micro-cracks during the curing process, enhancing the overall integrity and service life of the concrete elements.

- Fibras de acero For structural applications requiring high tensile strength, such as tunnel linings and industrial facilities, steel fibers offer unmatched durability. They distribute loads more evenly and increase the concrete’s load-bearing capacity, making it ideal for heavy-duty applications.

- Fibras de celulosa Sustainable and eco-friendly, cellulose fibers are utilized primarily to enhance the environmental profile of precast elements. They improve the fire resistance and thermal insulation properties of concrete, which is essential for building construction and infrastructure projects.

Applications of Fiber-Reinforced Precast Concrete

- Building Construction In residential and commercial buildings, precast panels reinforced with Fiberego fibers provide enhanced structural integrity, faster construction times, and superior aesthetic finishes.

- Bridge Construction For bridges, precast beams and deck panels reinforced with fibers ensure longer spans and greater load capacities, reducing the need for frequent maintenance.

- Tunnel Lining Fiberego fibers are critical in the production of precast tunnel segments, offering enhanced durability against the harsh underground environment and reducing permeability.

- Industrial Facilities In facilities where chemical exposure and mechanical stresses are common, fiber-reinforced precast elements resist wear and corrosion, thereby safeguarding structural integrity.

- Infrastructure From retaining walls to sewage systems, fiber-reinforced precast concrete stands up to environmental challenges, ensuring long-term stability and functionality.

Future Trends and Innovation

Fiberego continues to innovate in the field of fiber-reinforced precast concrete. The company is exploring the integration of nanotechnology to develop even more advanced fibers that could further enhance the mechanical properties and sustainability of precast concrete.

Conclusión

Fiberego’s commitment to enhancing precast concrete with specialized fibers transforms the landscape of construction and infrastructure. By providing materials that are not only structurally sound but also environmentally friendly, Fiberego is setting new standards in the precast industry, paving the way for more resilient and sustainable construction practices.